Straight Seam ERW Pipe Roll Mold Customersized

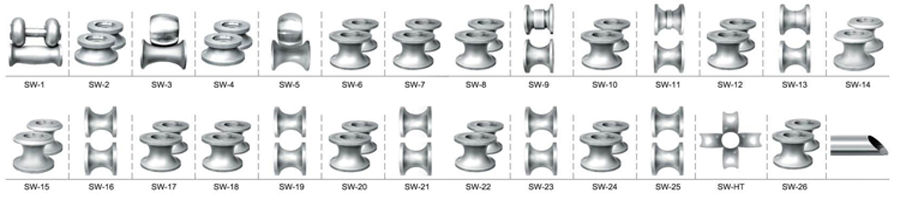

Finished shape

Schematic diagram of the flight

product description

According to customer requirements, experienced designers use CAD/CAM technology, relying on the technology synchronized with the world, through the world's advanced design software and rich design experience verification, scientifically optimize the design, strictly select raw materials, fine processing, vacuum heat treatment, careful inspection, production The whole process is controlled to ensure 100% factory qualified.

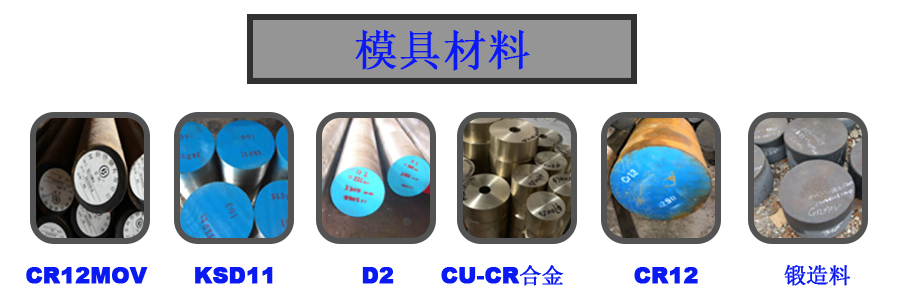

Mold material

Detailed description

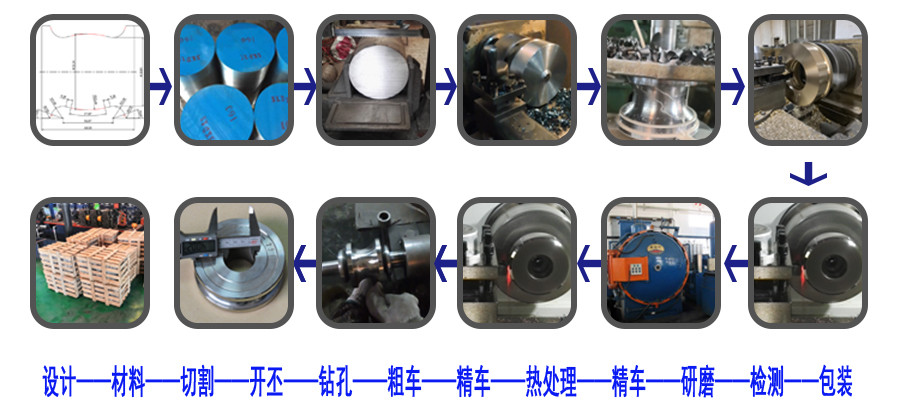

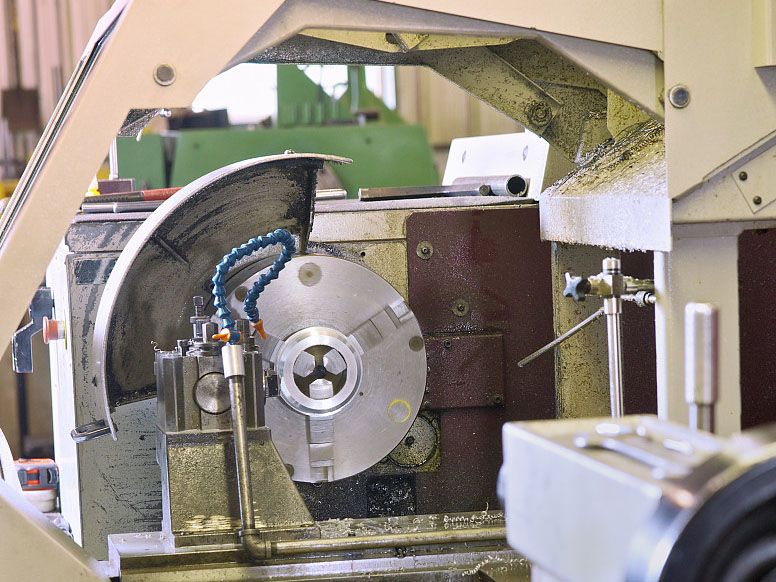

Processing technology: optimized design - careful material selection (solemnly promise that all applied materials comply with GB/T12999 and ASTM A681) - initial cold machining rough turning (skilled machine tool operators process in strict accordance with the drawings) - special hot machining heat treatment (vacuum heat treatment is adopted, with uniform hardness and longer service life) - precision machining (high-precision CNC lathe, to ensure the accuracy requirements of products) - fine grinding - polishing - quality inspection (professionals conduct 100% testing of all products) - Packaging - after-sales service (experienced engineers provide all-round technical support) and other processes.

Design-Material-Cutting-Opening-Drilling-Rough Turning-Fine Turning-Heat Treatment-Fine Turning-Grinding-Testing-Packaging

Product application

The large-scale straight seam roll mold is the main hub of the production of welded pipe equipment, and is the main accessory that determines the shape and diameter of welded pipe. It is mainly used in the production equipment of large-diameter straight seam welded pipe, and the production and manufacturing pipe diameter is greater than φ 100 welded steel pipe. Applied to some equipment and produced some products are as follows:

application

raw material chemical composition

After-sale service

Our company has a group of senior after-sales personnel with rich experience, which can well solve all kinds of mold repair problems, and strongly support the satisfaction of the company's users. Strictly abide by the provisions of the contract and provide customers with continuous maintenance and replacement of molds during the after-sales service period. After the warranty period, considering the continuity of the production products of the welded pipe equipment, it is recommended that customers sign a maintenance contract with our company to ensure the technical support and management support necessary for the normal operation of the welded pipe equipment line.

After sales service period = warranty period + quality maintenance period

Quality assurance period: during the quality assurance period, if the mold cracks due to quality problems, it will be replaced free of charge. If the failure is caused by non quality problems, the mold cost will be charged.

Quality maintenance period: after the quality assurance period, it enters the quality maintenance period.

ONE-STOP SERVICE SYSTEM

Logistics packaging

The export moulds of our company all adopt professional export packing wooden cases. Because the Customs has certain requirements for the export wooden cases when they are exported, the appearance of our wooden cases is smooth, without scratches, and the color is consistent. The raw materials of wooden cases can be inspection free plates that meet the export requirements. Usually, composite plates with a thickness of 9mm-15mm are used, some of which are also called plywood or plywood. They can also be wooden cases made of solid wood, which are then fumigated and disinfected, and formal fumigation treatment is issued to meet the export requirements.